|

Making Rice Husk Pellets in Vietnam |

I. Necessity of Rice Husk Pellet Production in Vietnam

II. Processing Rice Husk into Value-added Form

III. Current Situation of Biomass Energy Development in Vietnam

IV. Prospect of Biomass Pellet Production in Vietnam

Making Rice Husk Pellet in Vietnam

Rice husk or hull is the outermost layer of the paddy grain that is separated from the rice grains during the milling process. In Vietnam, rice husk was largely considered as a waste product that was often burned or dumped on landfills, which results in environmental problems. When searching for a way to use these husks as an energy source in place of fuel oil, rice husk pellets are turn out to be the right way. Some companies are turning into biomass pellet production by rice husk pellet plant, which not only for the eco-conscious market place but also for the industrial sector. Making rice husk pellets in Vietnam is the wise and economical investment!

I. Necessity of Rice Husk Pellet Production in Vietnam

1. Abundant and stable raw materials

Vietnam is the second biggest rice exporter and the world’s seventh-largest consumer of rice in the world, not surprisingly, also produces vast amounts of rice husk. Rice production has continuously increased every year. Vietnam 2014 paddy rice production is around 45 million tons, up 2% from last year. Rice husk is produced in large quantities in hundreds of thousands of rice mills all over the country and in 2014 approximately 9 million tonnes of raw husk is available.

Vietnam has two large rice production centers: the Mekong delta region in the South accounts for 50% of total rice production and the Red river delta area in the North produces about 20%. There are 3 main rice cultivation seasons in Mekong delta, and Red river delta can plant two seasons of rice per year. The production of rice husk depends on the supply chain of the paddy market, where paddy is usually stored, processed and sold based on the market demand. Therefore, rice husk production is more or less stable throughout the year.

|

|

|

2. Current Use of Rice husk

The current practices of rice husk in Vietnam: 15% for domestic cooking, 40-50% as fuel for brick kilns, 10% for power plant and briquette and 20-25% left over. Direct combustion of rice husk, however, is the common practice among brick kilns and power plant. There is presently work underway to develop rice husk pellet for use and instead of direct combustion.

3. Rice Husk Superiority as Biomass Fuel

Rice husk has rich crude fiber content, lingnocellulos and cellulose 40%, and five-carbon sugar polymers, also named as hemicelluloses 5%. The bulk density of rice husk is 96-160kg/m³,which will be higher after crushing. Ash content is around 15-16% and moisture content is around 12%. Rice husk’s caloric value is about 14 MJ/kg, which equaling 35% of the caloric value of diesel or bunker oil with a caloric value of 40.5 MJ/kg.

Rice husks is just like woods, which is a good material for fuel pellet production. The component comparison of the rick husk and woods are shown in the following forms for your reference.

|

Property

|

Rice husk

|

Wood

|

|

Carbon (%)

|

Around 35.0

|

48

|

|

Hydrogen (%)

|

4.0-5.0

|

6.5

|

|

Oxygen (%)

|

31.0-37.0

|

43

|

|

Nitrogen (%)

|

0.23-0.32

|

0.5

|

|

Sulphur (%)

|

0.04-0.08

|

NA

|

4. Advantages of Pelletizing Rice Husk into Pellet

|

|

|

As a source of alternative energy over the usual non-renewable fossil fuels, rice husk pellets have been gaining a lot of interest all over the world. Now rice husks are collected and transported from various rice mills to rice husking process plant for rice husk pellets production for the following advantages of rice husk pellets.

a. Good to environment

Rice husk pellets as a biomass fuel will ease the environment pressures caused by fossil fuel combustion. Comparing with the burning of rice husk, the burning of rice husk pellets is much more clean. The ash content is around 15 to 16 % when burning directly which will be largely decreased to 6 to 7 % when it is burned in pellet form.

b. Convenient

Rice husk pellets are highly densified and compacted into small size, which make their storage and transportation much easier and convenient. On the other hand, the small, regular and uniform shaped rice husk pellets make the feeding of automated heating system more easily.

c. High effectiveness

Comparing with burning directly, rice husk pellets can burn longer and the combustion rate of rice husk pellets can be above 95%. The characteristics comparison of rice husk and rice husk pellets are shown is the below form, for your reference:

|

Material

|

Average diameter

|

Ash content

|

Average density

|

Moisture content

|

Calorific value

|

|

Rice husk

|

2-3mm

|

15-16%

|

500kg/m3

|

About 12%

|

10-14kj/kg

|

|

Rice husk pellet

|

8-10mm

|

6-7%

|

1120kg/m3

|

7-8%

|

15-16kj/kg

|

Comparing with wood, rice husk pellets is also proved effective. Rice husk pellets has a low moisture content of 7 to 8%, which doesn’t need to consume energy to burn it off, making the burning of rice husk pellets effective.

d. Wide application

Rice husk pellets can be applied in many appliance. It can be burned in heating furnaces, boilers, pellets stoves and traditional stoves, and other heating systems.

II. Processing Rice Husk into Value-added Form

1. Rice Husk Pelletizing

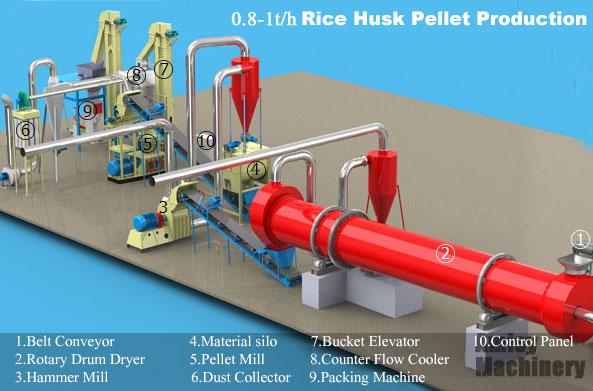

Drying-Pelletizing-Cooling and Packing

a. Drying

Rotary drum drying machine is mainly used to dry rice husk in large quantity.The target is to decrease the moisture content of rice husk for the pellet production.

Note: If your rice husk material moisture is less than 18%, the drying process is not necessary.

|

|

|

b. Pelletizing

Then the rice husk pellet making machine compress rice husk powder into pencil sized pellets. For large scale pellet production, you can choose ring die pellet machine. For small scale or homemade pellet making, please opt flat die pellet mill.

c. Final product cooling and packing

After pelletizing, rice husk pellets through belt conveyors are delivered into the cooling machine for cooling down to the temperature that meets packaging requirements. Then to sieve pellets by vibrating screen. At last final products go into the bunker. Now the whole production line has been finished.

Notice: In the processing of rice husk pellet, binders are recommended for better pellet quality.

● Mixing rice husk with proper raw dusts

During pelletizing, the lignin in saw dusts will be melted under the high temperature in the pellet mill and the melted lignin will work as a binder to help the formation of rice husk pellet.

● Mixing rice husk with bagasse

25% of rice husk and 75% bagasse; or 50% of rice husk and 50% bagasse

2. Rice Husk Briquetting

Rice husk can also be processed into briquettes whose procedures are similar to pelletizing. After rice husk crushing and drying, then feed the rice husk powder into biomass briquette machine and rice husk briquettes could be easily produced. In Vietnam, production of rice husk briquettes have become more common, supplying a valuable fuel for small and medium industrial boilers.

Advantages of rice husk briquettes

● Rice husk briquettes are economical by about 20% compared to coal.

● Lower pollution while briquette burning due to low ash, sulphur content compared to coal.

● Easy storage, handling transportation of rise husk briquettes, higher combustion efficiency and sustained high intensity burning compared to loose husk.

III. Current Situation of Biomass Energy Development in Vietnam

Realizing the importance of biomass energy in sustainable economic development, Vietnam in the last decade has prioritized investment into developing energy sector infrastructure and policy. The government has formulated policies for biomass energy development such as:

●Minimize the traditional use of biomass

●Encourage and support different researches to improve technologies and equipment of biomass energy application as biofuel, biopower and bioproducts.

●Adopt advanced technologies of reducing cost in biomass accumulation and transportation

●Create and develop biomass and biomass energy markets

●Enhance international collaboration for researches and develop technologies on biomass utilization.

Vietnam is a producing country. Cheap technologies are produced or imported, often of low qualities. When products break or stop working, it is inexhaustible fixed. Therefore technologies in biomass energy production have a much longer lifetime in Vietnam. Amisy is one of the well known manufacturers and exports of fuel pellet machines and pellet production lines. There is an expert team of technicians who are responsible for the delivery, assembling and installation and can provide you professional & patient guidance to efficiently operate the machine.

IV. Prospect of Biomass Pellet Production in Vietnam

Rice husk pellet is economical in Vietnam in heat production in industrial factories. The use of rice husk pellets in industrial boilers should be increased and supported. Now there are only few small rice husk power plants in operation in Vietnam, and many other power plants that are under development phase in different parts of Vietnam. The main fuel in these power plants will be rice husk pellets. Moreover, rice mills in Mekong River Delta are mainly located along rivers so it is convenient to transport rice husks by boat. So it is the promising investment to building rice husk pellet production line in Vietnam. Besides rice husk, rice husk pellet plant is also suitable for other agricultural waste like rice straw, bagasse, coconut shells and etc.

The European Union is the engine of the biomass pellet market. There is strong demand in the European heating sector as high energy prices drive consumers to look for fuel alternatives. Obviously, it offers great market for Vietnamese pellet and briquette production! To fulfill Europe’s demand in pellets Vietnam can export its pellets. Please note that pellets for the European market have to be produced according to the German DIN 51731 norm (or other wide accepted norms) to be interesting for large scale application.