Main Biomass Size Reduction Equipment

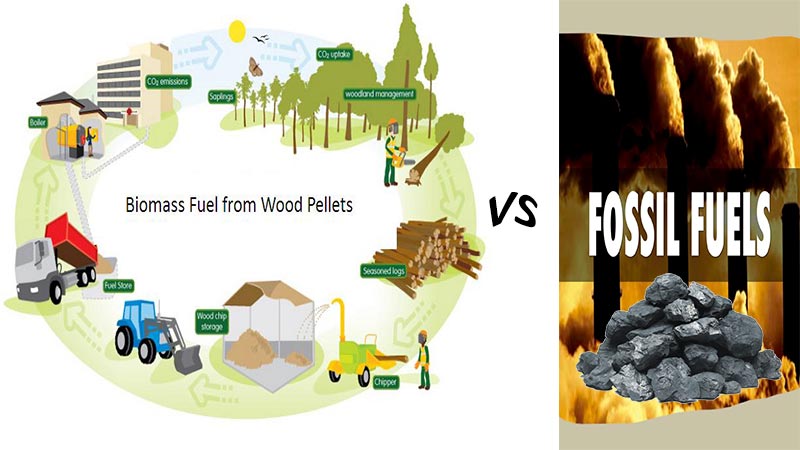

Historically, biomass utilization was limited to the wood industry, which has burned residues from different manufacturing processes. Recently there has been an expansion as more businesses are searching for ways to utilize biomass and cut back on greenhouse gas emissions. In the meantime, biomass handling systems are being developed fast, like biomass size reduction system, biomass pelletizing system, and biomass briquetting systems, etc. Among these, biomass size reduction system is the first and necessary processing equipment for biomass utilization as an energy. Biomass size reduction equipment for sale includes wood crusher, wood chipper, wood chipper shredder and wood hammer mill. Wood crusher, wood chipper and wood chipper shredder are used to process logs or large pieces of wood; while wood hammer mill is mainly used to pulverize wood chips or small diameter biomass materials like stalks, straw, grass and so on.

Size reduction process and its position in the whole process

Hammer Mills for Sale

Wood hammer mill for sale in the global market are small hammer mill for personal use and medium-to-large sized wood hammer mill for commercial use. Small wood hammer mills for sale such as electric wood hammer mill and diesel wood hammer are mainly used at home, farms or small sized wood pellet mill; and commercial use wood hammer mills with large capacity are mainly used at large biomass processing industry like wood pellet plant or charcoal briquettes plant.

How Does the Wood Hammer Mill Work?

A wood hammer mill uses impacts of rotating hammer mills to crush and grind biomass materials to the required sizes. Generally speaking, if you want to get fine products, the wood hammer mill should be set at a fast shaft speed, small screen and large number of hammer mills; if you want to make coarse product, the wood hammer mill should be set at a slower speed, large screen and few hammer mills. According to the material’s characteristics and the production purpose, shaft speed, screen size and number of hammer mills can be changed individually or in combination to achieve the best size reduction effect.

|

|

|

Specifications of Wood Particles as Fuel

The application of ground wood particles determines the selection of the size reduction equipment. Here is the summary of wood fuel specifications by burner type.

|

Device size range

|

Particle size

|

Moisture content

|

||

|

Pile burners

(wet cells) |

Up to 40 GWt

|

Virtually any kind except wood flour

|

Limited by grate size

and feed opening |

<65%

|

|

Thin-pile

Spreader-stoker |

Sawdust, non-stringy bark shavings,

end cuts, chips and chips rejects, hog fuel |

6-50mm

|

10-50%

|

|

|

Under-fire

Stokers |

Sawdust, non-stringy bark shavings,

chips, hog fuel |

6-38mm

|

10-30%

|

|

|

Suspension,

cyclonic |

1.5 MW-3 GWt

|

Sawdust, non-stringy bark,

shaving, flour, sander dust |

6mm max

|

<15%

|

|

Suspension,

air Spreader-stoker |

Sawdust, non-stringy bark,

shaving, flour, sander dust, hog fuel |

6mm max

|

<10%

|

|

|

Fluidized bed

combustors |

15-900 MWt

|

Virtually any kind

except wood flour and stringy materials |

50mm max

|

<60%

|

|

Gasifiers,

Fixed bed |

17 MWt-24 GWt

|

Chip, hog fuel

|

6-100mm

|

<20%

|

|

Gasifiers, FBG

|

2.5-50 MWt

|

Virtually any kind

except wood flour and stringy materials |

6-50mm

|

15-65%

|

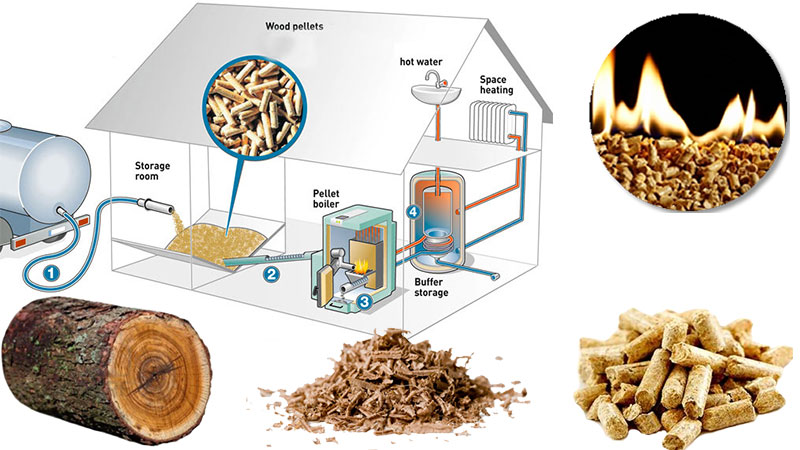

The particle size needed for the production of densified fuels such as wood pellets, briquettes. For making wood pellets or briquettes, wood hammer mill grinder is the dominant pre-processing equipment.

|

Particle size needed

|

Overall shape

|

Dimension(mm)

|

Density(kg/m3)

|

|

|

Pellets

|

< 6mm

|

Cylindrical

|

6/8/10/12 Dia.

|

700

|

|

Briquettes

|

< 6mm

|

Cylindrical

|

50-100 Dia.

|

1000-1500

|

Wood Hammer Mill Grinder for sale by Amisy Machinery

|

|

|

|

Model

|

FSP56*36

|

FSP56*40

|

FSP60*30

|

FSP60*45

|

FSP60*60

|

FSP60*75

|

FSP112*40

|

|

Capacity

|

2.5–5t/h

|

4–7t/h

|

2–5.5t/h

|

5–9t/h

|

6–10t/h

|

8–13t/h

|

12–22t/h

|

|

Diameter of rotor

|

560mm

|

560mm

|

600mm

|

600mm

|

600mm

|

600mm

|

1120mm

|

|

Width of chamber

|

360mm

|

400mm

|

300mm

|

450mm

|

600mm

|

750mm

|

400mm

|

|

Hammer NO.

|

20

|

24

|

24

|

44

|

48

|

60

|

40

|

|

Speed of rotor

|

2980r/min

|

2980r/min

|

2980r/min

|

2980r/min

|

2980r/min

|

2980r/min

|

1440r/min

|

|

Power

|

18.5/22kw

|

30/37kw

|

18.5/22kw

|

45/55kw

|

75/90kw

|

90/110kw

|

90/110kw

|

FSP series wood hammer mills are the best choice for commercial biomass processing. And for small biomass processors, we can also offer small wood hammer mill.