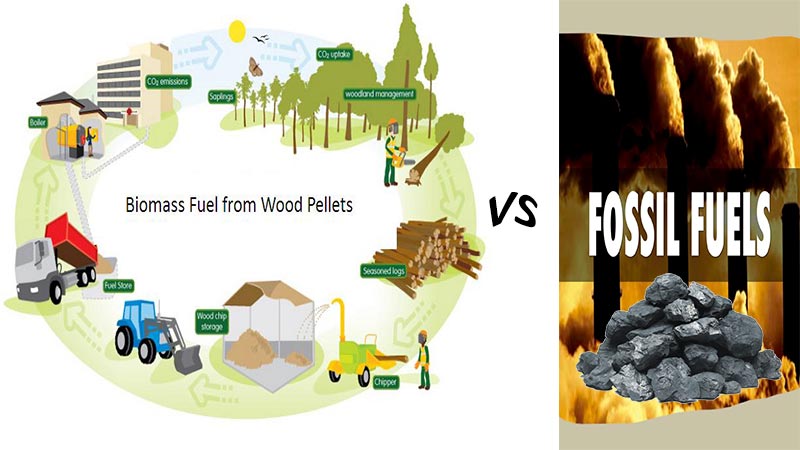

Wood pellet equipment from Amisy Pellet Machinery processes and converts all types of lignocellulosic biomass to be used as a clean energy in a pelleted form. The majority of biomass materials for wood pelletizing equipment come from three sources: forests, agriculture and wastes. However, non-forest conservation lands, like grasslands, savannahs and algaculture are also potential biomass sources for bioenergy. Regardless of sources, the biomass materials can be divided into two categories: woody and non-woody. Forests provide only woody materials and agriculture sources provide both woody and non-woody biomass for biomass pelletizing. Lignocellulose, composed of cellulose, hemicellulose and lignin is tightly bound in the plant cell walls. It is lignocellulose that makes them can be pelletized by wood pellet manufacturing equipment into solid fuel. The most common biomass pelletized by wood pellet making euipment for fuel is wood, mainly from sawdust, wood chips and shavings. Non-woody biomass generally has more hemicellulose and less cellulose and lignin than wood, giving it less tensile and compressive strength. Amisy Machinery has been testing the most suitable compression ratio of pelletizing equipment and the best combination of biomass suited for pellet production and combustion for its clients. Amisy wood pellet equipment has successfully coverted many non-woody materials, such as corn stover, sugarcane bagasse into solid fuel pellets.

Wood Pellet Manufacturing Equipment Pelletizing Processes

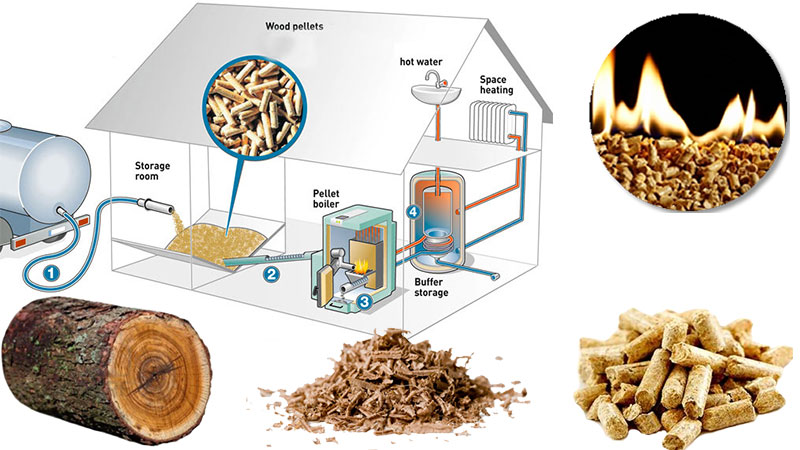

The main wood pellet equipment for wood pelletzing is composed of wood hammer mill, sawdust drying machine and wood pellet making machine. And other auxiliary wood pellet production equipment for sale is wood pellet cooling machine, wood pellet grading machine and wood pellet packing machine. These auxiliary wood pelletizing equipment is mainly used for commercial wood pellet manufacturing equipment.

The production of wood pellets begins with the cleaning of biomass materials to get rid of foreign materials. The clean biomass is then ground in a wood hammer mill to a uniform size which is less than 6mm. The smaller the size of biomass materials, the less power consuming the wood pelletizing machine. If the feedstock in high in moisture content, it must be dried by sawdust drying machine to about 8%-15%; if the material is too dry, water should be added. Then the prepared materials are fed into the wood pellet mill. In the pelletizing chamber, rollers pressed the materials through the flat die or ring die, which effectively condenses the materials into pellet form. When wood pellets come out the wood pellet making machine, they are hot; so in order to get hard and durable wood pellets, hot pellets need to be cooled. Then the cooled wood pellets are screened by the pellets grading machine to remove the fines and crumbled pellets. At last the graded pellets are bagged by pellets packing machine for easy handle, storage or transportation.

Amisy wood pellet equipment is a turnkey solution for wood pelletizing and what wood pellet processing equipment should be equipped is based on the clients’ raw material, production scale, pellet production purpose and the site of installation of wood pellet production equipment, etc. Saving cost as well as optimizing pelletizing efficiency and pellet quality for the clients are the pursuit of Amisy wood pellet equipment. Youtube videos of Amisy wood pellet manufacturing equipment and the whole wood pellet plant pelletizing processes will give you the clear idea of pelletizing technology and pelletizer mill equipment.

|

|

|

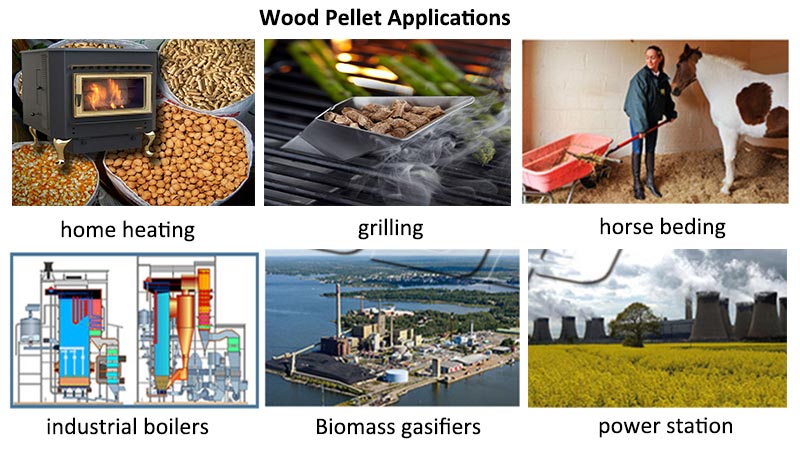

Applications of Pelleted Fuel Produced by Wood Pellet Making Equipment

● Heating

Wood pellets are used in freestanding stoves, fireplace inserts or in furnaces and boilers or in large public and commercial building for heating.

● Animal bedding

Along with moisture and odor absorbing qualities, wood pellets as animal bedding are becoming popular, and animal owners can collect and compost the resulting mix of wood pellets and manure.

● Electricity production

Wood pellets can be used in large pulverized fuel or circulating fluidized bed power plants for electricity production. Power plants can use 100% wood pellets or wood pellets co-firing with coal to generate power.