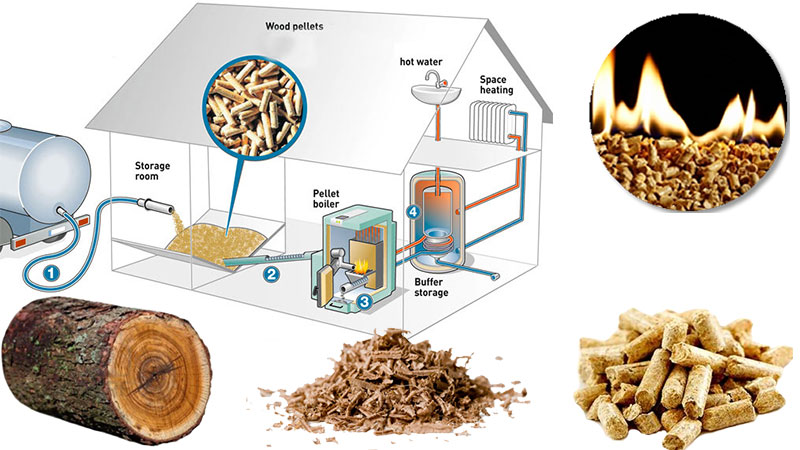

Recently, biomass pellets in Vietnam gains great appreciation and the ring die pellet mill is becoming more and more popular in wood pellets plant among wood pellet suppliers in Vietnam.

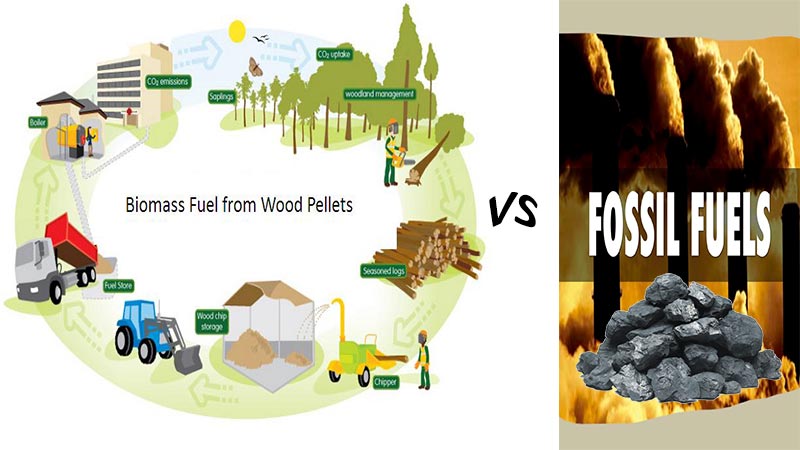

In the last decade, the fast industrialization and economy progress lead to a rapid growth of fossil energy consumption in Vietnam. In order to avoid energy barriers and protect the environment,the Vietnam government formulates several policies to increase the share of renewable energy in total commercial primary energy.Despite the obstacles of electricity purchase, high investment of equipment and technical knowledge, biofuel pellets gain great development and come to blossom after building a series of cooperation with the Dutch.

Vietnam is the second largest country in exporting rice in the world.Rice husk can be directly used for rice husk pellets. Based on the survey, it was concluded that rice husk was the most suitable raw material for bio-pellets in Vietnam. Its process is relatively simple. After simple treatment, rice husk can be feed in the rice husk pellet mill.With the large amounts of rice produced, rice husk is already utilized in Vietnam on a larger scale.In practical production, the ring die pellet mill is generally accepted by rice husk pellet plants.

Why Choose Ring Die Wood Pellet Mill

According to the analysis,in the total number of pellet machine,the proportion of the ring die pellet machine in Vietnam has increased sharply since 2012.Through investigation and analysis,we think that there are several reasons of people using the ring die pellet mill in Vietnam rice husk pellets processing.

*High production efficiency. In industrial production, the ring die pellet mill is more suitable for the large capacity production,300-3500kg/h than the flat die,30-2000kg/h,shortening the product time thus reducing the production cost.

*Ring die wood pellet mill adopts imperative feeding device, ensuring a continuous & even feeding speed. Flat die pellet mill adopts vertical feeding way,that is to say,materials depend on its own weight dropping into the pelletizing chamber.So the feeding speed of flat die pellet mill cannot be controlled automatically.

* The roller shell of ring die pellet mill for making biomass pellets doesn’t completely cover the roller, reducing wear and prolonging a longer service life.

*Ring die pellet mill can be equipped with inner oil spraying device,making pellets surface more smooth and solid.