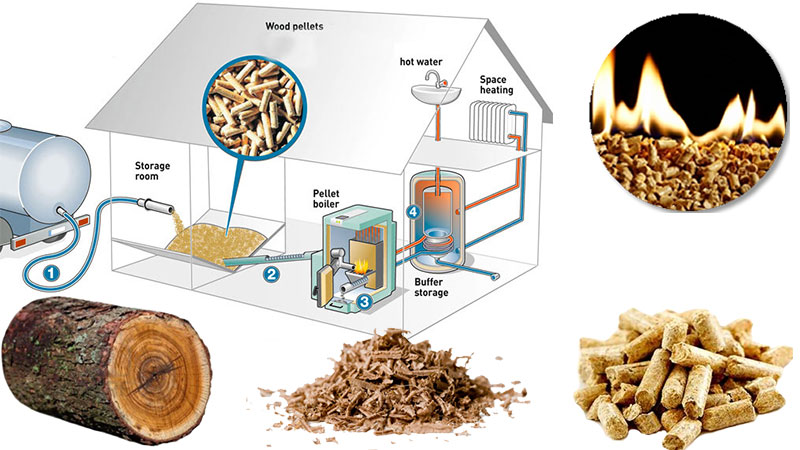

Wood pellet mill is a specialized machine to manufacture wood pellets. High quality wood pellet mill will be helpful to produce good quality wood pellets. However, the water content of raw materials when processing is also very important to the quality of wood pellet.

Wood pellet mill can divide into two different kinds: extrusion type wood pellet mill and rolling type wood pellet mill.

For the extrusion type wood pellet mill, it requires that the water content of the raw materials should limit to 15% to 25%, the  water content of shaped pellet should limit to 15%-23% and the surface water content of wood pellet been aired or cooled should about 14%-18%. Usually we can judge the water content of raw materials through the feel of touching or the conditions of the pellets after pressing. If you feel the raw materials are wet, rough, cool and the materials can squeeze to balls, the water content of raw materials is in proper range. In addition, you can also judge the water content through the extrusion conditions of the wood pellet mill. If the output and flour yield of the wood pellet is too high, the temperature is too low, and there is smoke when been extrusion, the water content of the raw materials is too high. While if the output is low, the temperature of the pellet is high, the quality of the pellet is poor and there is a noise in the machine, the moisture of the raw materials is too low. In order to produce high quality wood pellet ,you should adjust your water content of raw materials accordingly.

water content of shaped pellet should limit to 15%-23% and the surface water content of wood pellet been aired or cooled should about 14%-18%. Usually we can judge the water content of raw materials through the feel of touching or the conditions of the pellets after pressing. If you feel the raw materials are wet, rough, cool and the materials can squeeze to balls, the water content of raw materials is in proper range. In addition, you can also judge the water content through the extrusion conditions of the wood pellet mill. If the output and flour yield of the wood pellet is too high, the temperature is too low, and there is smoke when been extrusion, the water content of the raw materials is too high. While if the output is low, the temperature of the pellet is high, the quality of the pellet is poor and there is a noise in the machine, the moisture of the raw materials is too low. In order to produce high quality wood pellet ,you should adjust your water content of raw materials accordingly.

For the rolling type wood pellet mill, since water should be added in the manufacturing process, the requirement of the water content of raw materials is not as strict as for extrusion type wood pellet mill. With different raw materials, the water content of them are also different. Thus the water should be added in is also changeable.

To control the water content of raw materials is very important for the wood pellets making which will not only guarantee the smooth operation but also assure the output and quality of the wood pellets, so the water content of raw materials should especially be valued.